Trusses

Roof trusses are the predominant industry standard method for building roofs. Usually, roof trusses are used when the span or width of a building exceeds 16 ft. (for lesser widths rafters are usually more economical)

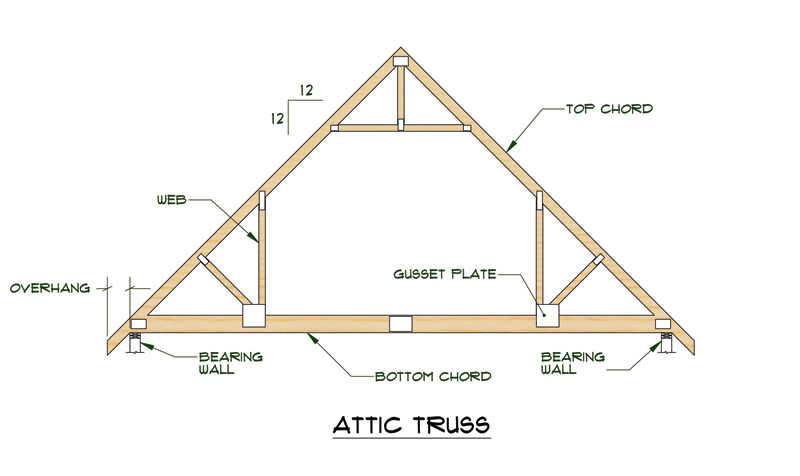

A roof truss is a load carrying, spanning member made of wood components (usually 2x material), connected together with metal plates or plywood (gussets). Used together with other trusses, often spaced at 24" on centers, the roof loads are carried out to the walls efficiently.

Trusses are designed as a package, fabricated according to state laws and engineered as part of their manufacture. (Engineered means that loads applied to the trusses and resulting stresses in the materials are analyzed and components sized to carry the required local loads for the specific spans and truss shapes. This is typically done with specialized industry standard software (ie. MiTek, Alpine) as well as under the supervision of a state-licensed engineer.) The truss system is treated as a distinct, pre-engineered component of the building structure and engineer stamped/signed documentation is delivered with the truss package. Metal plate connected wood trusses, typically used in residential construction, are designed per the ANSI TPI 1-2014 publication as referenced within the governing building code.

Trusses shapes are almost unlimited in possibilities. Attic and Gambrel truss profiles are becoming popular due to the economy of structure and additional floor space they offer.

The truss shown above is known as an Attic Truss or a Room-In Attic Truss. This type of truss carries a combination of Roof (Lr or S) and Floor (L) loading in addition to the standard top and bottom chord Dead loads. Proper analysis of an attic truss requires multiple load cases with multiple duration factors. It is also an indeterminate structure with a non-triangulated web area, which interrupts the normal flow of forces thru the truss. Indeterminate structures cannot be solved using the equations of static equilibrium, instead matrix analysis (direct stiffness method), using a combination of frame and truss elements, is commonly employed.

Truss deflections are limited by code requirements, typically the deflection due to live load for roof trusses is L/240. Trusses can be cambered for the dead load portion of the deflection. In theory, once the dead loads are applied, the truss deflects downward giving a level ceiling line. In addition to immediate load induced deflection, wood trusses will also experience what is called creep. Creep is property of wood that causes trusses under sustained long-term loading to deflect more and more with time. This can increase the calculated dead load deflection by two to three times.

Calculation of truss deflections is usually with the virtual work method with an additional factor "S" added for the plate slip or nail slip at each joint.

Visit our Truss Gallery for a more in-depth look at some of the more common truss designs used in our plansets.

Calculate your roof snow load for common trussses, rafters or attic trusses with our Snow Load Calculator.

Estimate your roof truss requirements with our Truss Designer.

Create accurate 3D truss geometry within SketchUp with our Truss Plugin.

Rafters

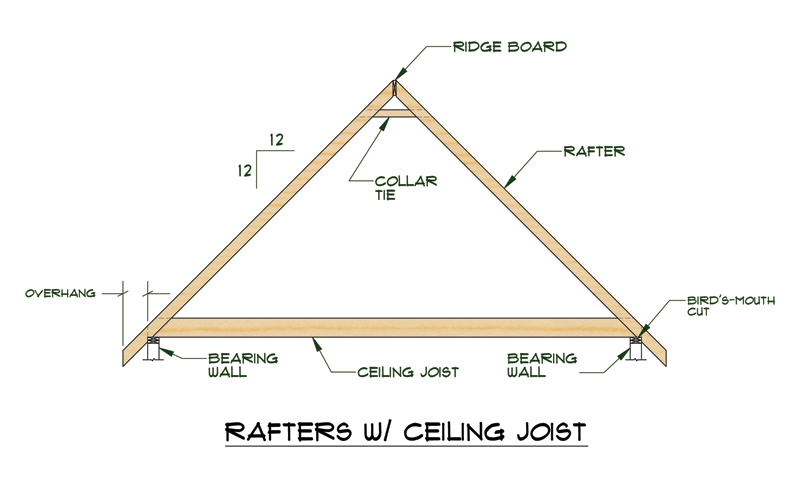

Rafters with Ceiling Joists are often used for smaller roof spans or widths, typically less than 16 ft, due to greater economy.

Each rafter spans from the bearing wall to the ridge board at the roof peak, half the distance between the two walls, and are sized per the building code for span, spacing, load, slope, wood species and grade. The continuous ridge board secures the roof peak assembly. The ceiling joist acts as a tension tie to keep the rafters from splaying out under load and also creates a ceiling surface. Ceiling joists are typically located on the top plate of the walls but may also be located higher to form a partially vaulted ceiling. A collar tie is also commonly used in the upper third of the roof height below the ridge board to secure the rafter pairs against uplift, spaced at a minimum 4 ft. o.c. The rafters are typically spaced at 16" o.c. or 24" o.c, is completely prescriptive in the code and so usually requires no additional engineering.

All our plansets include a roof framing (layout) plan, a cross-sectional view and a truss/rafter details sheet which illustrate either the roof framing or the recommended truss profile (which serves as a basis for the truss engineering and manufacture by the truss supplier/fabricator). Usually, when ordering trusses through your materials supplier or setting up your project with your builder, you can request adjustments to the profile shown (ie. to match an existing house, change the overhang, or adjust roof pitch).

If you have any questions about trusses or rafters please contact us.